Bridging the Supply Chain Revolution: Data, Talent, and Technology Convergence

The global supply chain landscape stands at a transformative crossroads where data-driven insights, advanced technology, and augmented workforce capabilities are reshaping how businesses operate. As we navigate 2025, organizations are increasingly recognizing that traditional supply chain management approaches are insufficient to meet the complex demands of modern commerce.

The Data-Driven Imperative

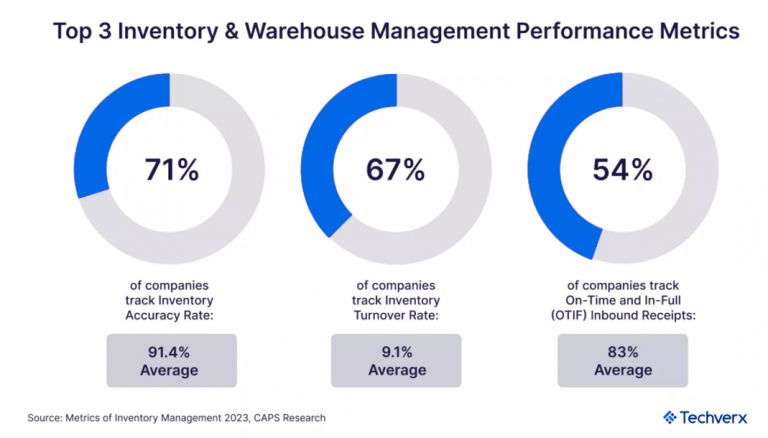

Supply chains today generate unprecedented volumes of data, from IoT sensors tracking shipments in real-time to customer behavior analytics predicting demand patterns. The transformation to data-driven supply chain management represents more than a technological upgrade; it’s a fundamental shift in how organizations approach decision-making. Companies leveraging advanced analytics report up to 20% increases in efficiency and are twice as likely to achieve above-average financial performance.

However, the statistics reveal a concerning gap between potential and reality. While 84% of companies have adopted or plan to adopt data-driven strategies, only 6% have achieved full end-to-end supply chain visibility. This visibility paradox underscores a critical challenge: having data isn’t enough, organizations need the capability to transform raw information into actionable insights.

The power of predictive analytics extends beyond simple forecasting. Modern supply chain analytics encompass three critical layers: descriptive analytics for understanding past performance, predictive analytics for forecasting future trends, and prescriptive analytics for providing optimal action recommendations. Companies implementing these comprehensive analytics approaches can reduce process costs by up to 50% while increasing revenue by 20%.

The Augmented Workforce Revolution

As artificial intelligence and automation reshape supply chains, a new paradigm is emerging: the augmented connected workforce (ACWF). This approach doesn’t replace human workers but enhances their capabilities through intelligent technology integration. By 2026, Gartner predicts that 50% of office workers in global enterprises will be AI-augmented in some form.

The augmented workforce model addresses one of the most pressing challenges facing supply chains today: the critical talent shortage. An alarming 90% of supply chain leaders feel their companies lack the necessary talent and skills to achieve digitization goals. Traditional hiring methods often prove too slow and expensive, particularly for specialized roles requiring niche expertise in emerging technologies.

Staff augmentation emerges as a strategic solution, enabling organizations to rapidly access specialized talent without the long-term commitments of traditional hiring. This approach is particularly valuable in supply chain management, where companies need expertise in areas ranging from data analytics and AI implementation to sustainability compliance and risk management. The global staff augmentation services market, valued at $299.3 billion in 2023, is projected to reach $857.2 billion by 2031.

Technology Convergence Driving Transformation

The convergence of multiple technologies is creating unprecedented opportunities for supply chain optimization. Gartner identifies several key trends shaping 2025, including ambient invisible intelligence through ultra-low-cost sensors, polyfunctional robots adapting to multiple tasks, and intelligent simulation enhancing predictive capabilities.

Artificial intelligence applications are particularly transformative. Agentic AI systems can autonomously execute decisions and optimize inventory management based on real-time demand forecasts. Meanwhile, generative AI is being adopted across supply chains, with 80% of organizations planning to pilot or implement GenAI capabilities and dedicating 6% of their technology budgets to these investments.

The Internet of Things (IoT) plays a crucial role in this technological convergence, with over 80% of logistics companies planning to integrate IoT for real-time tracking, inventory optimization, and loss prevention. Digital twins technology provides another layer of optimization, with companies using digital twins reporting a 30% decrease in supply chain disruptions.

Addressing Critical Challenges

Despite technological advances, supply chains face mounting challenges that require integrated solutions combining data, talent, and technology. The data reveals stark realities: 76% of supply chains are affected by workforce shortages, while 62% of companies have limited supply chain visibility. Additionally, 55% of businesses cite geopolitical instability as a major concern for supply chain resilience.

These challenges create a compelling case for augmented talent solutions. Organizations need professionals who can navigate complex data analytics platforms, implement AI-driven optimization tools, and manage cross-functional teams in increasingly digital environments. Staff augmentation provides the flexibility to scale teams based on project demands while accessing specialized expertise that may not be available in-house.

The Strategic Implementation Framework

Successful supply chain transformation requires a strategic approach that integrates data capabilities, workforce augmentation, and technology adoption. Organizations should begin by assessing their current visibility gaps and identifying where augmented talent can provide immediate impact. This might include bringing in data scientists for advanced analytics implementation, supply chain engineers for process optimization, or AI specialists for automation projects.

The staff augmentation model offers several advantages for supply chain transformation: rapid deployment of specialized skills, cost-effectiveness compared to full-time hiring, and the ability to scale teams based on project requirements. Companies can leverage augmented talent for specific initiatives such as implementing predictive analytics platforms, optimizing logistics networks, or developing sustainability reporting systems.

Key success factors include establishing clear integration protocols for augmented staff, ensuring knowledge transfer between external experts and internal teams, and maintaining strong project management oversight. Organizations should also focus on building internal capabilities over time, using augmented talent not just as a temporary solution but as a catalyst for long-term capability development.

Industry Applications and Success Patterns

Leading organizations across industries are demonstrating the power of integrated approaches to supply chain transformation. In manufacturing, companies are using augmented reality for workforce training while simultaneously implementing IoT sensors for real-time production monitoring. Retailers are combining demand forecasting algorithms with augmented logistics teams to optimize inventory levels and improve customer satisfaction.

The key to success lies in recognizing that technology alone cannot drive transformation—it requires the right combination of data insights, technological tools, and human expertise. Augmented workforce models provide the bridge between advanced technology capabilities and practical implementation, ensuring that organizations can fully leverage their digital investments.

Building Resilient Supply Chains for the Future

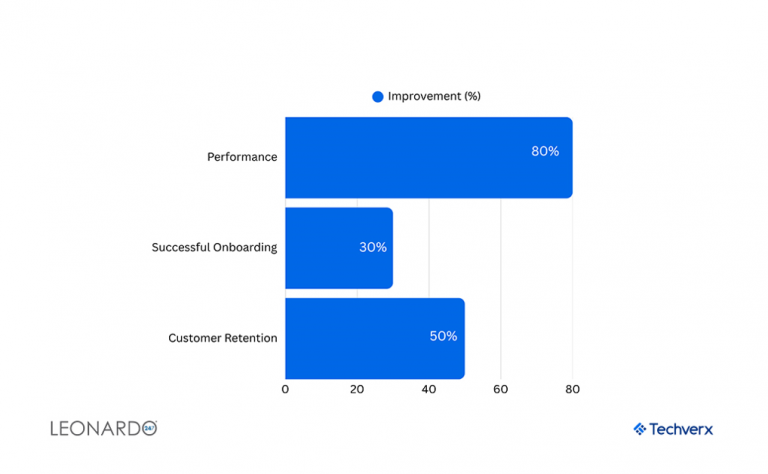

Before concluding, it’s worth examining how these principles apply in practice. Consider Leonardo247, a property management platform that faced challenges very similar to those found in supply chain operations today: disconnected teams, coordination gaps, and mounting technical debt.

Through strategic staff augmentation with Techverx, a dedicated team of senior engineers and project managers was embedded to stabilize systems, improve delivery velocity, and modernize the platform architecture. The results were substantial:

This transformation demonstrates the power of Techverx’s augmentation model combining deep technical expertise, agile delivery practices, and close cross-functional collaboration. It offers a compelling parallel for supply chain organizations seeking to drive operational improvements without the delays or overhead of traditional hiring.

Conclusion

The future of supply chain management lies in the strategic convergence of data analytics, advanced technology, and augmented workforce capabilities. Organizations that embrace this integrated approach, leveraging data for insights, technology for automation, and Techverx’s staff augmentation model for execution, will build supply chains that are not only more efficient but also more resilient and adaptable.

The statistics are clear: companies must act decisively to bridge the gap between technological potential and operational reality. By partnering with providers like Techverx, businesses can access domain-specific talent faster, scale projects based on demand, and accelerate the implementation of AI, predictive analytics, and automation tools.

Whether it’s launching a digital twin initiative, integrating real-time tracking systems, or building sustainability reporting pipelines Techverx helps organizations execute smarter, faster, and with less risk.

The transformation journey requires commitment, strategic vision, and the right partnership model. Those who begin that journey now, with Techverx as a trusted execution partner will be best positioned to lead in tomorrow’s complex global marketplace.

Hiring engineers?

Reduce hiring costs by up to 70% and shorten your recruitment cycle from 40–50 days with Techverx’s team augmentation services.

Related blogs