Beyond Dashboards | Building an Insight Layer with Predictive AI

How Predictive AI Builds a Smarter Insight Layer

Most enterprises do not have a dashboard problem; they have an insight problem. AI-powered dashboards and predictive analytics only create value when they sit on top of an integrated “insight layer” that connects ERP, supply chain, and retail data into real-time, action-oriented decision support.

Dashboards Are Rearview Mirrors

Traditional BI and ERP analytics were built to answer “what happened?” using historical data refreshed in batches. In many enterprises, refresh cycles still run nightly or even weekly, while decisions about inventory, pricing, and logistics now operate on hourly horizons.

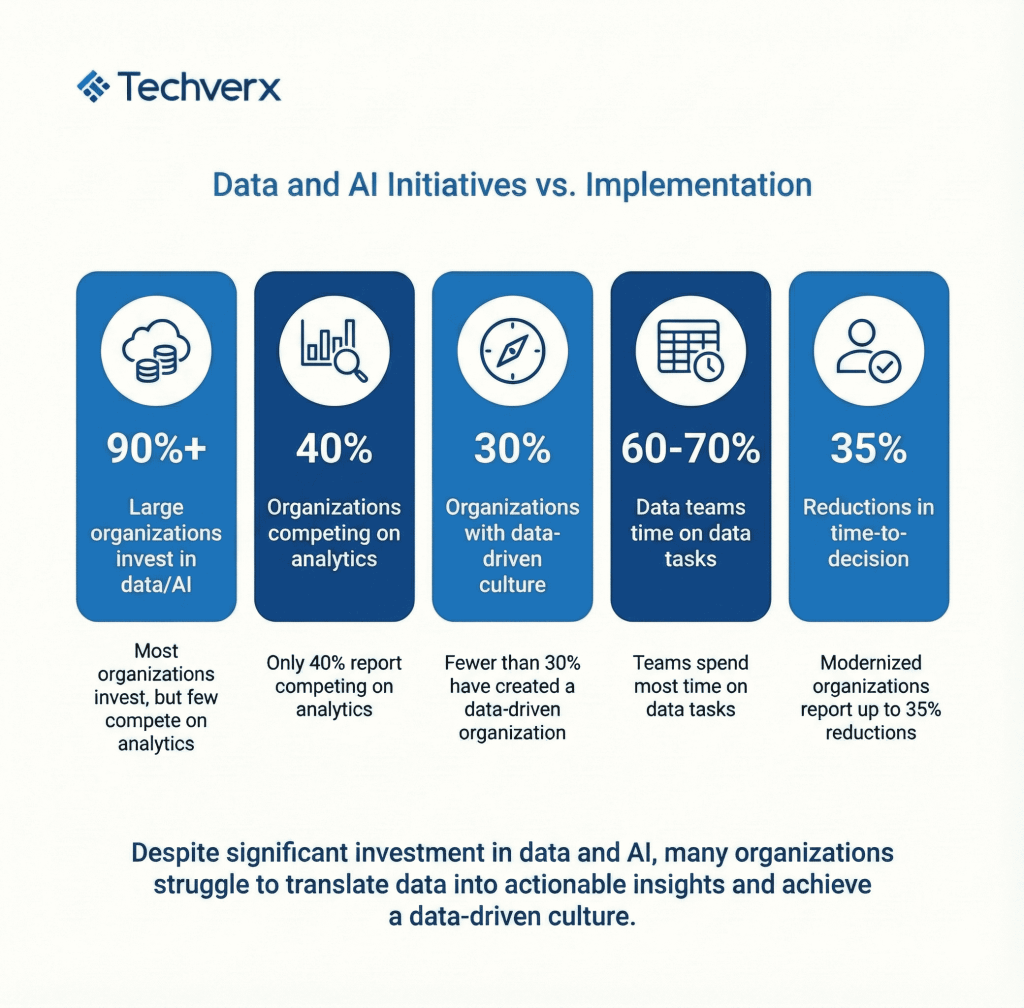

Studies of modern analytics programs show that teams spend more than 60% of their time hunting for data and reconciling definitions instead of making decisions.

That waste shows up in supply chain KPIs: delayed visibility into demand spikes or supplier failures directly contributes to stockouts, excess inventory, and margin leakage.

The Insight Layer: Your Missing Middle Tier

The insight layer re-architects analytics from a reporting surface into a decision engine. Instead of dashboards pulling from static tables, AI models and agents sit between operational systems (Dynamics 365, WMS, POS, e‑commerce) and decision-makers.

Vendors working with semantic layers and AI-driven analytics report up to 2–3x faster time-to-insight when teams query a unified semantic model instead of raw tables.

The same stack also reduces conflicting KPIs, because there is a single governed definition of metrics such as fill rate, on-time delivery, and available-to-promise.

Why Historical Reporting Fails Operations

Relying on historical dashboards creates three systemic issues that no amount of visualization polish will fix. First, data latency means by the time a KPI appears as red, the underlying event, promotion spike, port delay, carrier failure has already propagated through the network.

Second, ERP, SCM, TMS, and e‑commerce platforms rarely share context in real time, so leaders see fragmented views of demand, supply, and profitability. Third, static reports focus on variance reporting; they show the gap but not the viable corrective playbook, forcing analysts back into spreadsheets and ad-hoc SQL.

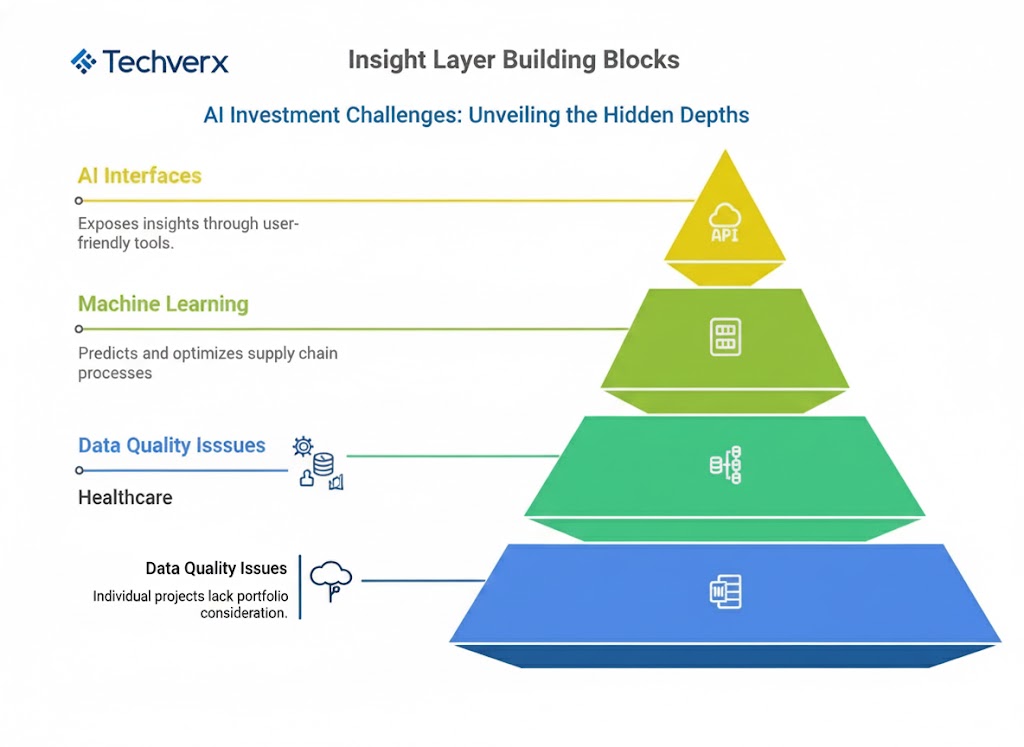

Four Building Blocks of the Insight Layer

A practical insight layer for enterprise supply chains contains four capabilities.

- Semantic backbone: kill metric confusion

A governed semantic layer normalizes products, orders, locations, and customers across Dynamics 365 and adjacent systems, so AI can reason over a single business vocabulary. Platforms that invested in this approach report dramatically lower “metrics confusion” and smoother adoption of AI assistants across teams. - Low-latency data pipelines and feature store

Streaming pipelines ingest IoT events, sales orders, shipment updates, and returns into a low-latency store, exposing model-ready features such as sell-through velocity, lead-time variability, and promotion uplift. Vendors using real-time vector and feature stores for analytics show meaningful gains in responsiveness and the ability to support real-time AI experiences at scale. - ML that moves inventory and margin

Machine learning models perform demand forecasting, inventory risk scoring, supplier reliability prediction, and pricing elasticity estimation across ERP and SCM data. Advanced programs report forecast-error reductions in the 20–30% range when moving from traditional methods to ML-based, multi-signal models, particularly in retail. - AI-driven decision interfaces

AI dashboards, natural-language interfaces, and AI agents expose these capabilities as predictive dashboards, plain-language narratives, and “next best action” recommendations. User studies on conversational analytics show significant reductions in time-to-answer and cognitive effort compared to traditional self-service BI interfaces.

Where ERP and SCM Must Finally Talk

Most “beyond dashboards” content stops at architecture diagrams and never gets specific about ERP and SCM integration. Techverx focuses on three concrete patterns with Dynamics 365 at the core.

- Demand signal fusion for real-time forecasting

POS, e‑commerce orders, marketing campaigns, and historical ERP sales are fused into ML-based demand forecasts by SKU, location, and channel.

Case studies show that when marketing, retail, and ERP signals are integrated, forecast accuracy can improve by double digits and safety stock can be reduced while maintaining service levels.

- Constraint-aware supply planning

Dynamics 365 SCM purchase orders, supplier lead times, production schedules, and transportation capacity feed a single constraint model. Predictive models estimate disruption probabilities and recommend alternate sourcing, expedited routes, or inventory buffers, cutting reaction times from days to hours when a constraint emerges. - Profitability-centric allocation

ERP financials, SKU margin profiles, and supply chain costs are blended with demand forecasts to recommend where each unit of inventory generates the highest return. Enterprises that align allocation with profitability instead of simple fill-rate targets report meaningful uplift in gross margin and reduced markdowns.

AI Dashboards vs AI Agents

AI dashboards matter, but they are still pull-based: users must log in, navigate pages, and interpret patterns. AI agents are push-based and behavior-aware, monitoring streams of metrics and triggering interventions when thresholds are crossed.

Emerging research and case studies show that AI agents embedded into operational workflows can cut reaction times and reduce reliance on manual monitoring.

In IT operations, LLM-powered assistants have already reduced mean time to resolution from hours to minutes by accelerating root-cause analysis and recommending remediation steps; the same pattern applies to logistics disruptions and demand spikes.

Dynamics 365 in an Insight-Layer World

In a Dynamics 365-centric environment, the insight layer becomes the real nerve center.

- Predictive replenishment

Predictive dashboards surface projected stockouts, excess inventory, and reorder recommendations across warehouses and stores, driven by ML forecasts and live on-hand balances from Dynamics 365. When enriched with external and channel signals, such replenishment systems have been shown to materially reduce both stockouts and working capital tied in overstock. - Promotion and pricing intelligence

By combining ERP sales, retail promotions, and historical uplift, models estimate cannibalization and margin impact before execution. Enterprises using AI-driven promotion analytics report measurable increases in campaign ROI and faster feedback loops, sometimes compressing performance readouts from weeks to days. - Supplier reliability scoring

The insight layer aggregates purchase orders, receipts, quality issues, and lead-time variability from Dynamics 365 SCM to score suppliers on reliability and risk. When these risk scores directly drive sourcing and safety-stock policies, organizations report improved on-time performance and fewer surprises at critical nodes.

Turn Dashboards Into Predictive Intelligence

Decision Surfaces That Talk Back

Interfaces built on the insight layer change how leaders and planners work.

- Conversational ERP analytics

LLM-powered conversational analysts let executives ask, “Why did on-time delivery drop in the Northeast last week?” and receive narrative answers plus recommended actions.

Organizations adopting conversational analytics report faster decision cycles and broader analytics adoption beyond specialist teams.

- Role-based AI dashboards

AI-enhanced dashboards adapt layout, KPIs, and narrative explanations for COOs, planners, or store managers without duplicating logic.

This reduces dashboard sprawl while increasing relevance, because every user interacts with the same governed insight layer through their own lens.

- Proactive “next best action” flows

Instead of waiting for monthly reviews, AI agents push targeted notifications inventory risk, margin erosion, SLA breaches along with recommended next steps that can be accepted or adjusted.

Organizations piloting such agents report sharper adherence to targets and fewer “unknown unknowns” surfacing at quarter-end.

A Blueprint CIOs Can Actually Execute

For CIOs and enterprise architects, this is not a dashboard refresh; it is an analytics modernization program with clear milestones.

- Map decisions, not reports

Start by cataloging high-value decisions in supply chain and retail, the data required for them, and the current time-to-insight. Use this map to prioritize where predictive and prescriptive analytics will drive the largest financial and operational impact. - Stand up the semantic and integration backbone

Use Dynamics 365 as the system-of-record anchor and design a semantic model that normalizes ERP and SCM entities across data sources. Adopt a cloud data platform capable of powering both BI and AI workloads while enforcing governance at scale. - Productize core machine learning models

Treat demand forecasting, inventory optimization, and supplier risk models as products with clear owners, SLAs, monitoring, and retraining schedules. Leading teams monitor not only accuracy but business impact service levels, working capital, and margin and adjust models accordingly. - Layer AI dashboards, conversational interfaces, and agents on top

After the insight layer stabilizes, scale investments in predictive dashboards, natural-language querying, and AI agents embedded into Dynamics 365 workspaces. Enterprises that follow this order data and semantics first, UI second avoid the common trap of impressive but untrustworthy “AI skins” on weak data.

Techverx is positioned to execute this blueprint end to end: designing the semantic and integration layer for Dynamics 365, engineering real-time supply chain pipelines, and delivering predictive dashboards and AI agents that convert ERP analytics into continuous, AI-driven decision support. For enterprises under pressure to move from reactive reporting to proactive, prescriptive supply chain intelligence, the strategic question is no longer whether to go beyond dashboards, but how quickly the insight layer can be designed, deployed, and scaled across the organization.

How does Techverx help enterprises move from static dashboards to an AI-driven insight layer?

Techverx designs and implements an “insight layer” that sits between your ERP, supply chain, and retail systems and your BI tools, combining data engineering, semantic modeling, and predictive AI so leaders get prescriptive recommendations instead of backward-looking reports.

Can Techverx integrate predictive dashboards directly with Dynamics 365 and existing ERP data?

Yes. Techverx’s Dynamics 365 consulting and data engineering teams build real-time pipelines, semantic models, and AI dashboards that sit natively on top of Dynamics 365, unifying finance, operations, and retail data for predictive analytics and AI-driven decision support.

What types of predictive and prescriptive use cases does Techverx typically deliver for supply chain and retail?

Techverx implements use cases such as demand forecasting, inventory optimization, supplier-risk scoring, promotion and pricing intelligence, and AI agents for inventory rebalancing and cash-flow optimization, tailored to each client’s supply chain footprint.

How quickly can Techverx help us pilot AI agents or predictive dashboards on top of our ERP and SCM data?

Techverx uses a staged delivery model starting with a focused pilot around a critical decision (for example, stockout prevention or forecast accuracy) and has proven patterns to stand up production-grade agents and predictive dashboards in as little as 60–90 days.

What makes Techverx a strong partner for enterprise analytics modernization compared to generic BI or AI vendors?

Techverx combines deep Dynamics 365 expertise, data engineering capabilities, and AI/ML services, enabling it to own the full stack from data pipelines and governance through to predictive dashboards, LLM-powered experiences, and AI agents embedded in operational workflows.

Amanda Hill

Amanda Hill is a Technology Implementation Specialist at Techverx, where she combines her expertise in data analysis, digital transformation, and project management to bring complex ideas to life. Passionate about innovation and operational efficiency, she helps clients seamlessly execute technology solutions that drive measurable impact.

Hiring engineers?

Reduce hiring costs by up to 70% and shorten your recruitment cycle from 40–50 days with Techverx’s team augmentation services.

Related blogs