Dynamics 365 for Retail & Omnichannel Solutions

Modern manufacturing is highly intricate, with countless interconnected processes. To manage uncertainty and tackle challenges such as supply chain disruptions, rising costs, and quality assurance, ERP solutions for manufacturers typically deliver capabilities like:

- Production planning and scheduling: Optimize workflows and minimize downtime.

- Inventory and materials management: Track raw materials, components, and finished products in real time.

- Bill of materials and routing: Handle complex product structures and streamline production workflows.

- Shop floor control: Monitor machine performance, workforce activity, and work-in-progress efficiently.

- Quality and compliance tracking: Ensure standards are upheld at every production stage.

- Demand forecasting and supply chain integration: Align production plans with market demand and supplier timelines.

Leading ERP platforms for manufacturing, like Microsoft Dynamics 365, go a step further by embedding AI capabilities. Features such as predictive analytics, automation, forecasting tools, and natural language interfaces make collaboration easier, improve visibility across operations, and support faster, data-driven decisions.

Benefits of ERP Solutions for Manufacturing

ERP solutions simplify manufacturing complexity and fuel growth in several important ways:

Improved Productivity

ERP software automates repetitive tasks, reduces manual data entry errors, and speeds up production cycles, allowing teams to focus on high-value activities.

Better Resource Management

A centralized view of inventory, equipment, and labor enables smarter allocation of resources. Real-time tracking of materials and capacity helps eliminate waste and keeps production running on schedule.

Enhanced Decision-Making

Real-time analytics and customizable dashboards give manufacturers instant insights into KPIs. From demand forecasting to process bottleneck detection, ERP provides the data needed for timely, informed decisions.

Increased Profitability

Greater efficiency and reduced downtime lower overhead costs and expand production capacity. With improved visibility into pricing, procurement, and performance, businesses can control costs at every stage and boost margins.

Regulatory Compliance and Quality Control

Many ERP platforms offer built-in compliance and quality tools that document each production step, mitigate risks, and ensure consistency across batches.

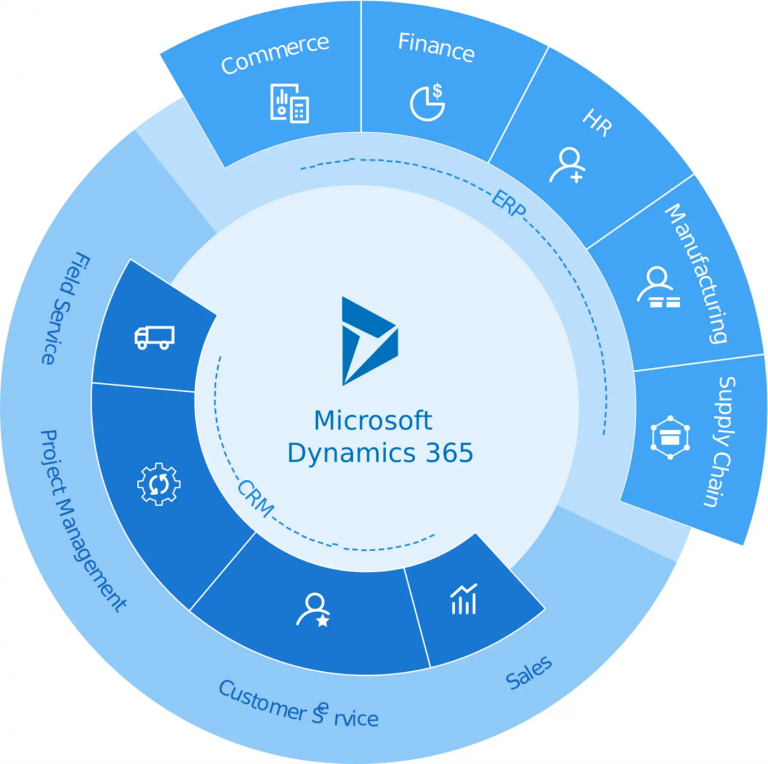

Key Features of Microsoft Dynamics 365

Dynamics 365 is designed with flexibility and scalability at its core, enabling manufacturers to stay competitive, cut through operational complexity, and embrace digital transformation confidently. Its standout features include:

- AI-powered insights: Leverages machine learning to analyze historical and live data for predictive maintenance, demand forecasting, and process optimization.

- Real-time analytics: Offers instant visibility across departments to support faster decisions.

- Automation tools: Streamlines procurement, scheduling, and reporting to cut manual effort and errors.

- Seamless integration: Works with CRM systems, IoT platforms, and product lifecycle management tools for a unified data flow.

- Scalable architecture: Modular design supports growth and customization without major disruptions.

- Mobile and cloud access: Enables remote management and collaboration from any device.

- Advanced inventory and production management: Tracks materials and production stages to reduce waste and improve fulfillment.

Streamlining Manufacturing Processes

ERP solutions like Dynamics 365 make manufacturing more agile by simplifying complex processes:

- Smarter production planning: Automatically generate production schedules using real-time inventory, order, and machine data.

- Real-time inventory visibility: Maintain optimal stock levels, reduce overproduction, and avoid shortages.

- Automated quality control: Ensure consistent product quality by embedding checks throughout the process.

- Cost and efficiency gains: Minimize duplicate work, reduce data errors, and improve interdepartmental coordination for faster delivery and lower costs.

Boosting Operational Efficiency

Manufacturing ERP systems improve day-to-day operations in several key ways:

- Workflow optimization: Map and refine production steps with full visibility and automated alerts to keep everything running smoothly.

- Downtime prevention: Use predictive analytics to monitor equipment health and schedule maintenance before failures occur.

- Cross-team collaboration: Break down silos by centralizing data and enabling shared dashboards, real-time communication, and coordinated decision-making across departments.

Supply Chain Management with ERP

An agile, resilient supply chain is critical for manufacturers. Dynamics 365 Supply Chain Management provides:

- Complete supply chain visibility: A centralized dashboard to quickly spot bottlenecks, reduce delays, and keep operations flowing.

- AI-driven optimization: Forecast demand, anticipate risks, and right-size inventory using machine learning insights.

- Better supplier collaboration: Supplier portals and real-time communication tools strengthen relationships and enable just-in-time manufacturing.

- Timely material availability: Automate purchase orders and sync inventory with production schedules to eliminate delays and reduce waste.

Deployment Options for Manufacturing ERP

ERP systems can be deployed in three main ways—cloud, on-premises, or hybrid—depending on business needs and IT strategy:

Cloud ERP

Cloud solutions are hosted remotely and accessed online, offering flexibility, scalability, and lower upfront costs.

Best for: Manufacturers prioritizing agility, cost savings, and easy maintenance.

On-Premises ERP

Installed locally and managed by internal IT, this option provides maximum control and customization but requires more infrastructure and maintenance.

Best for: Highly regulated manufacturers or those needing deep customization.

Hybrid ERP

Combines on-premises control with cloud convenience, enabling a gradual transition to full cloud adoption.

Best for: Manufacturers with legacy systems or those preferring a phased modernization approach.

Implementing ERP Successfully

A structured, phased rollout ensures a smooth transition. The process typically includes planning, data migration, configuration, testing, training, and go-live support. Key steps for a successful implementation:

- Set clear objectives: Define top challenges and measurable goals.

- Engage stakeholders: Get decision-makers involved early to secure buy-in.

- Cleanse and standardize data: Ensure accuracy before migration.

- Assess current workflows: Identify areas for automation and improvement.

- Plan for change management: Communicate early and train teams to ease adoption.

Microsoft Support and Resources

Techverx provide robust support throughout the ERP journey:

- FastTrack for Dynamics 365: Accelerates deployment with expert guidance and best practices.

- Migration assessment tools: Evaluate existing systems and create a tailored migration roadmap.

- Training resources: Access documentation, tutorials, and learning paths designed for manufacturing teams.

Common Challenges with ERP

Understanding common pitfalls helps manufacturers make better decisions:

- Complexity and rigidity: Traditional systems can be difficult to customize and maintain.

- Poor integration: Legacy systems may not connect well with other tools, leading to data silos.

- Limited real-time insights: Batch processing delays decision-making.

- High costs and long rollouts: On-premises deployments often involve hidden expenses and lengthy timelines.

- Low user adoption: Complex interfaces can discourage employees from using the system effectively.

Why Choose Techverx for Dynamics 365

Choosing the right ERP is only half the battle, finding the right partner to implement and optimize it is what makes the difference. Techverx specializes in turning Dynamics 365 into a true growth engine for manufacturers.

We start by working with you to map out your future state, analyzing your processes and designing a Dynamics 365 solution that’s scalable and aligned with your business goals. From there, our certified consultants handle configuration, integration, and testing to make sure everything runs seamlessly and your data remains clean and reliable.

But we don’t stop at go-live. Techverx offers change management, training, and ongoing support to ensure your team fully adopts the platform and you see maximum ROI. With our deep manufacturing expertise and strength in integrating Dynamics 365 with CRM, IoT, and other enterprise systems, we help you eliminate data silos, improve collaboration, and gain AI-driven insights that keep you competitive

Partnering with Techverx means you get more than an implementation team, you get a dedicated ally committed to making Dynamics 365 a catalyst for agility, efficiency, and long-term growth.

Ready to transform your manufacturing operations?

Schedule a free discovery workshop with our Dynamics 365 experts and see how we can help you move faster, smarter, and with confidence.

Hiring engineers?

Reduce hiring costs by up to 70% and shorten your recruitment cycle from 40–50 days with Techverx’s team augmentation services.

Related blogs