Smarter Stock Management with AI: Reducing Costs and Enhancing Customer Experience

The Day the Shelves Went Empty

It started with a single viral TikTok.

A 15-second clip of a fashion influencer twirling in a new denim jacket sent sales through the roof. Within 48 hours, the online store’s stock was gone, warehouses were empty, and customers were still clicking “Buy Now.” What should have been a dream moment turned into a nightmare of apologies, refunds, and lost loyalty.

Every retailer has lived some version of this story. One product goes viral, demand explodes, and supply collapses under the weight of success. Meanwhile, slow-moving inventory gathers dust, tying up capital that could have fueled growth elsewhere. The truth is, stock management isn’t about what’s selling now, it’s about what will sell next.

Traditional systems can’t keep up with that kind of volatility. Forecasts made with last quarter’s data feel like looking in the rear-view mirror while speeding down the highway. Manual spreadsheets, disconnected supplier updates, and guess-based replenishment aren’t just inefficient, they’re expensive. The cost shows up in emergency air shipments, wasted storage, and customers who don’t come back after seeing “Out of Stock.”

In one corner of the warehouse, the dashboard flashes red, alerts piling up faster than anyone can clear them. The system was never built for this kind of surge, but that’s the gap AI was built to close.

For a store pulling in $10 million a year, that’s $7 million in potential revenue vanishing into thin air. If you could claw back just 15% of that, you’d add over a million dollars to your bottom line without chasing a single new customer.

We know why this happens. Almost half of all abandonments are thanks to surprise shipping costs. Another quarter comes from websites forcing you to create an account. The rest are lost to checkout processes that feel like filing your taxes.

From Guesswork to Foresight

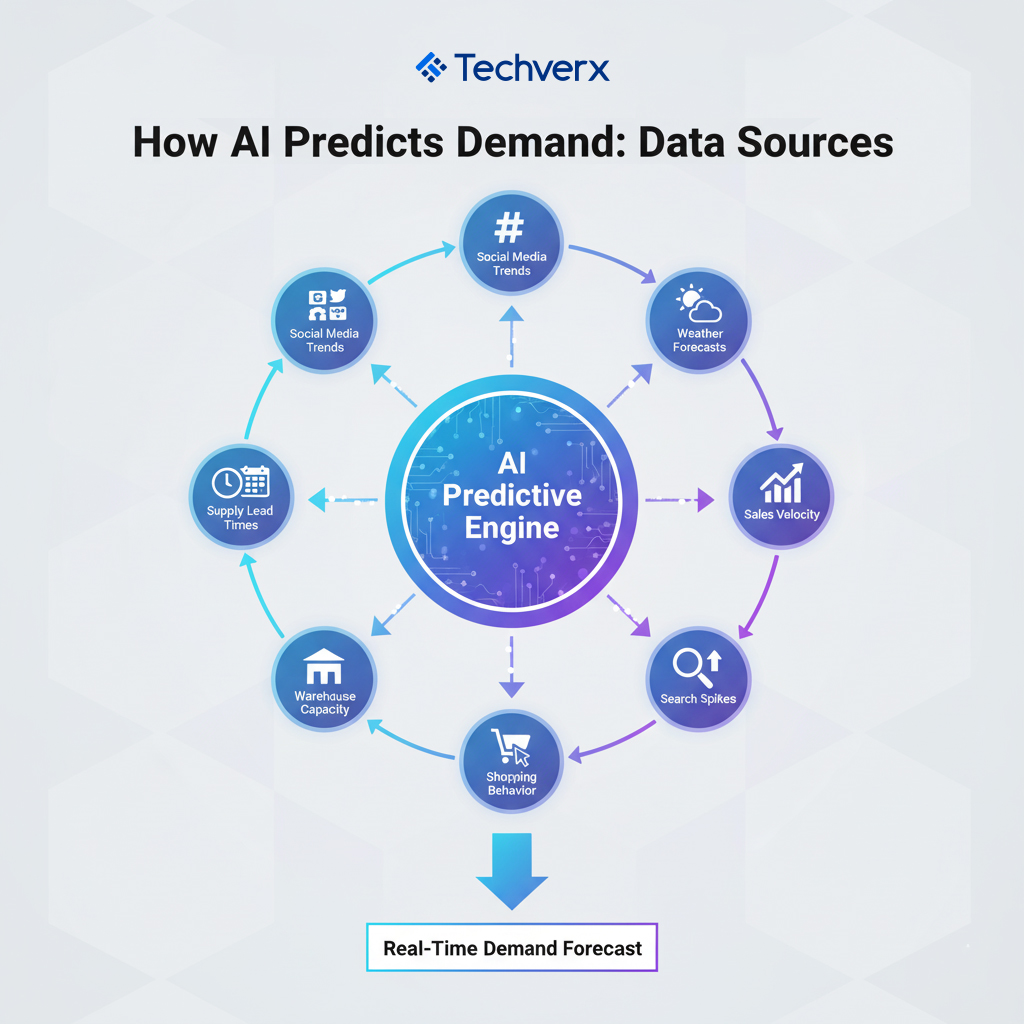

Modern AI in the supply chain turns stock management from reaction to prediction. Using predictive analytics and demand forecasting, it identifies early signals like social-media mentions, search spikes, and even weather trends that hint when a product is about to surge.

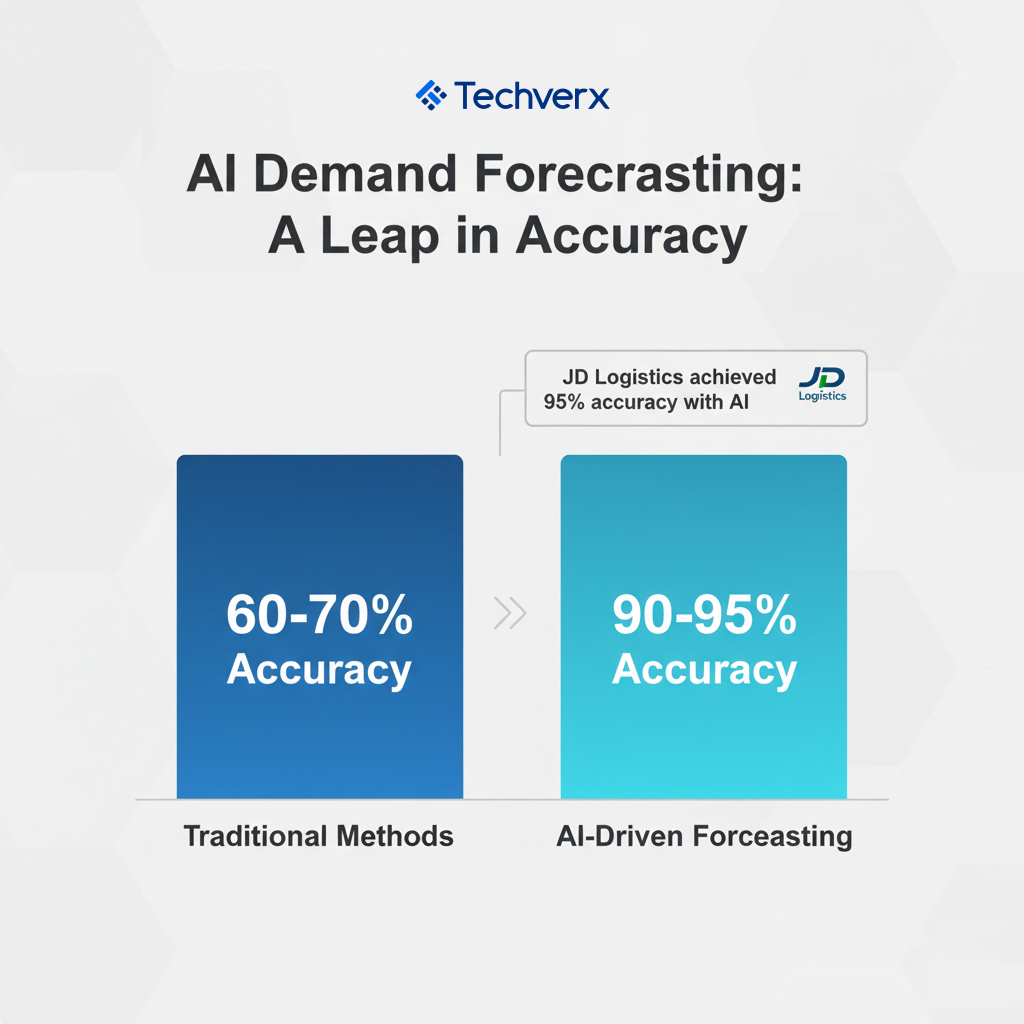

Across industries, the pattern is the same: AI sees what humans can’t, and acts before they do. JD Logistics reached over 95 percent forecast accuracy, even managing a 70 percent spike in overseas orders during Black Friday. Route optimization algorithms have cut logistics costs by up to 30 percent, and dynamic pricing engines like Amazon’s adjust 2.5 million prices daily to stay aligned with demand.

Inside a retailer’s system, that means no more surprises. The AI predicts that the denim jacket’s popularity will explode three days before it does. It alerts suppliers, shifts warehouse priorities, and ensures replenishment happens before customers even notice stock running low.

For the store manager, it means fewer sleepless nights and more control. Dynamics 365 and Microsoft 365 Copilot bring that intelligence to life, integrating sales data, marketing insights, and supplier updates into one living ecosystem. Managers no longer need to pull reports or rely on intuition, because Copilot surfaces trends, drafts forecasts, and suggests order quantities with full reasoning.

When predictive analytics replace guesswork, the result isn’t just accuracy, it’s confidence.

How AI Predicts Demand Before It Happens

AI models learn from patterns invisible to human analysts. They connect dots across the entire retail universe, studying sales velocity across regions, tracking weather forecasts and trending hashtags, observing what shoppers view, compare, or abandon, and accounting for supply factors like lead times and warehouse capacity.

Each signal adjusts a live forecast that updates by the hour, not the quarter. Over time, the model becomes a digital twin of the retailer’s operations, a mirror image that runs a few steps ahead of reality.

When demand spikes, the system doesn’t panic, it reallocates stock automatically. When sales slow, it eases replenishment to prevent overstock. This constant rebalancing cuts waste, stabilizes cash flow, and builds customer trust through consistency.

According to McKinsey, retailers using AI-driven demand forecasting see 10 to 15 percent higher revenue and retention than those relying on manual systems. And with 84 percent of e-commerce companies already adopting AI solutions, the competitive bar isn’t just rising, it’s racing ahead.

The Hidden Cost of Manual Operations

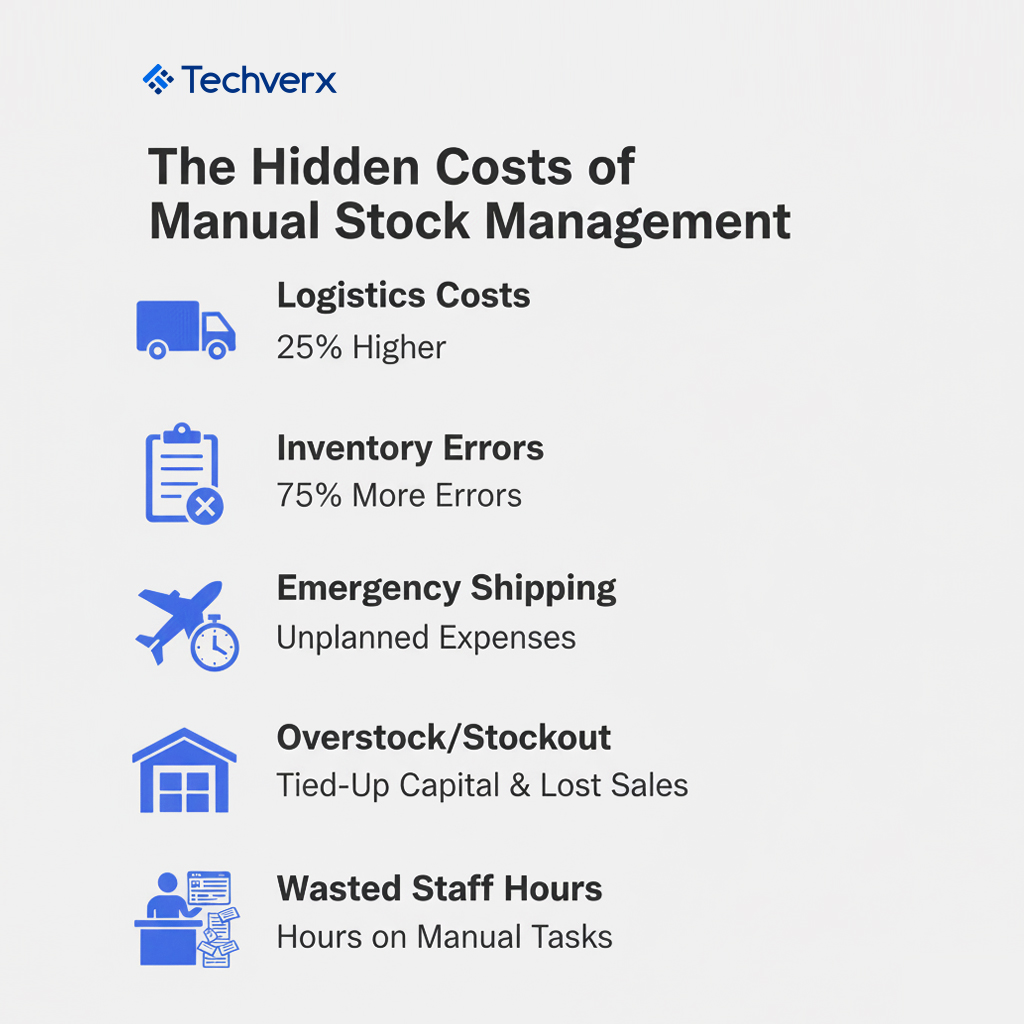

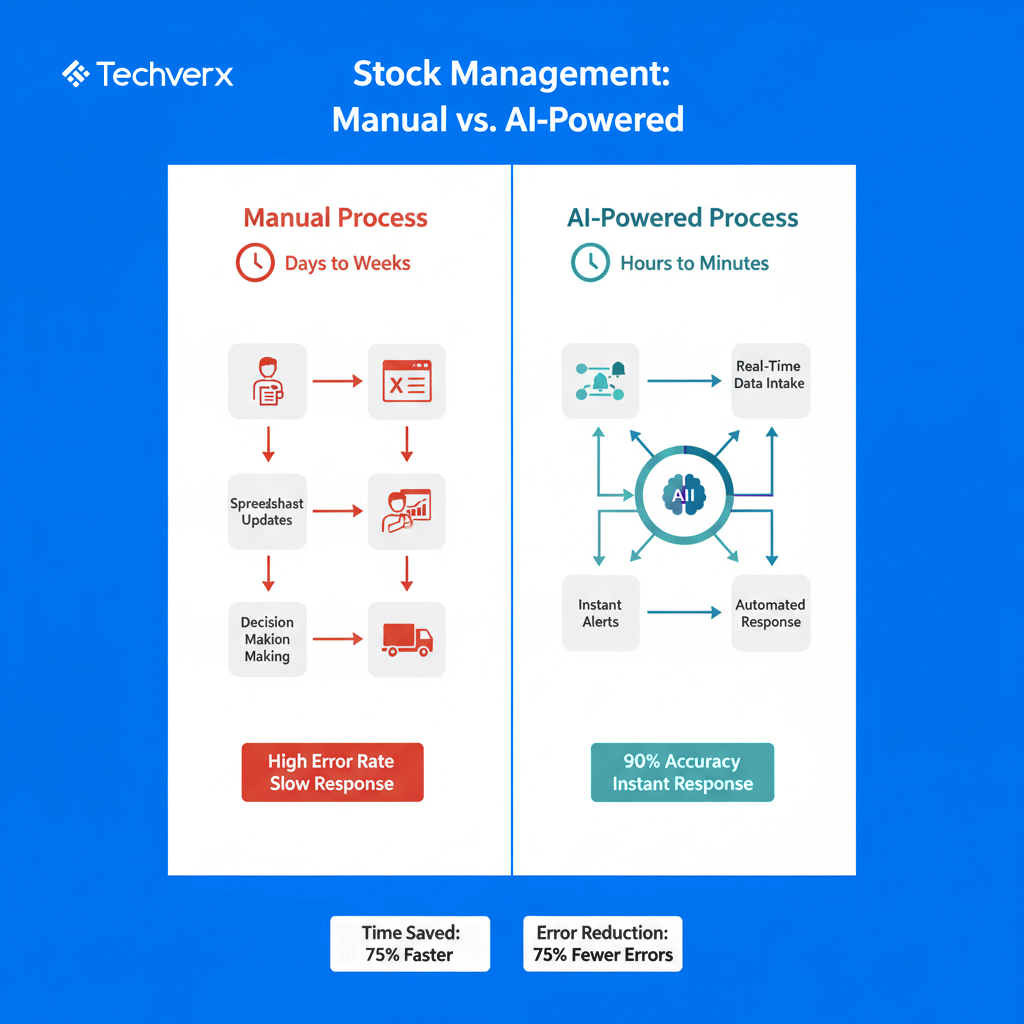

Before AI, stock management was a juggling act performed in slow motion. Inventory planners lived inside spreadsheets, watching rows of SKUs blur as they cross-checked supplier emails and updated numbers by hand. Each report took hours to compile, and by the time it reached anyone’s inbox, the data was already stale. It wasn’t forecasting, it was forensic work, done after the damage was done.

Those outdated processes carry quiet but brutal costs. Overstock fills warehouses with unsold goods that drain margins. Stockouts drive customers to competitors, while emergency restocks add expensive shipping fees that could have been avoided. Every manual task, every spreadsheet update, pulls skilled people away from strategy and traps them in maintenance mode.

In this cycle, errors multiply quickly. A single missed entry can throw off forecasts, budgets, and marketing plans. Finance loses trust in numbers. Marketing promotes products already sold out. What seems like a logistics issue is really a visibility problem, no one sees the whole picture!

McKinsey found that companies relying on manual demand planning face up to 25 percent higher logistics costs and 75 percent more inventory errors than those using AI-assisted forecasting. Gartner adds that integrating predictive analytics improves inventory accuracy by 20 to 30 percent in the first year. These aren’t abstract numbers, they’re daily losses that quietly drain profitability. The fix isn’t more manpower, it’s smarter insight.

Turn Your Inventory into a Strategic Advantage

When predictive analytics steps in, everything changes. AI reads what’s about to happen, not just what already did. It spots search spikes, regional shifts, and weather patterns that influence demand, adjusting stock levels before anyone notices. It learns from each transaction, becoming an invisible analyst that prevents inefficiencies before they cost money.

Retailers that have embraced AI-driven inventory optimization report cost reductions of up to 30 percent and forecast accuracy consistently exceeding 90 percent, according to Deloitte. But the real advantage goes beyond numbers. It’s the shift from firefighting to foresight. Managers can finally focus on customer experience instead of counting cartons. Finance teams can trust their data. Marketing can plan boldly, knowing supply can keep up.

Manual operations aren’t just costly, they’re exhausting. AI doesn’t replace the human expertise behind commerce, it amplifies it. It frees teams to think strategically instead of administratively. The brands that understand this are discovering something powerful, when machines handle the routine, people finally have room to innovate.

Where Customer Experience Meets Inventory

Stock management might sound operational, but its impact is deeply human. When a shopper clicks “Buy” and the item ships without delay, that moment builds trust. When it doesn’t, loyalty quietly erodes. Availability is invisible when it works and unforgettable when it fails.

AI bridges that emotional gap. It connects the logic of inventory intelligence with the empathy of personalization in retail. When systems know what’s in stock and what’s trending, they can recommend products that are both relevant and ready to ship. That’s upsell/cross-sell AI at its best, not a mindless carousel of “You might also like,” but a live conversation that adapts to real-time availability.

According to Salesforce, AI-powered recommendations influenced $229 billion in global e-commerce sales last year, nearly one-fifth of all online orders. It’s proof that the new frontier of customer experience isn’t just what brands say, it’s how precisely they deliver what customers want, right when they want it.

Dynamics 365 and Microsoft 365 Copilot: The Techverx Edge

At the center of this transformation are Dynamics 365 and Microsoft 365 Copilot, two platforms Techverx implements for enterprise retailers ready to modernize their operations. Dynamics 365 provides real-time visibility across finance, inventory, and logistics, while Copilot acts as an intelligent partner that summarizes patterns, drafts purchase orders, and flags anomalies before they become costly problems.

Together, they create the digital nervous system of a connected business. Every sale updates procurement. Every marketing push informs forecasting. Every supplier changes ripples through delivery schedules automatically. The result is movement, not maintenance but a system that reacts instead of waits.

Techverx engineers these integrations end to end, connecting Azure, Dynamics, and AI frameworks so data moves seamlessly and securely. What once took hours of cross-checking now happens in moments, giving decision-makers the clarity to anticipate instead of apologize.

The Future: From Reactive to Predictive Commerce

Graham Cook, a veteran of e-commerce innovation, calls this the third act of commerce, the AI Revolution following the Industrial and Web Revolutions. Power is shifting again, from companies guessing what customers want to systems that already know.

In the next decade, predictive analytics will not just balance inventory, it will design it. Digital twins of warehouses will run endless simulations, testing how supply chains react to factory

shutdowns, weather changes, or viral spikes in demand. Before a single product moves, the AI will already know which shelf it belongs on, which store needs it first, and how to reroute shipments when demand shifts overnight.

Generative AI, through tools like Microsoft Copilot, will act as the interpreter between complexity and clarity. It will translate millions of data points into human decisions, giving leaders visibility that once took days in seconds. Gartner predicts that by 2030, over 30 percent of retail supply decisions will be made by predictive models, not manual planners, a quiet but radical redefinition of how commerce operates.

The businesses adapting now are building an edge that compounds. Every restock sharpens the algorithm. Every order trains the forecast. Every correction makes the system smarter. The gap between reactive and predictive is widening, and those still planning by hindsight may find themselves running years behind.

Techverx: Building Intelligent Supply Chains

At Techverx, we help enterprises evolve from manual management to intelligent orchestration. Our engineers specialize in Dynamics 365, Azure, and enterprise AI integration, creating predictive ecosystems that connect inventory, forecasting, and customer experience into one living network.

From data unification and MLOps to cloud-native delivery and security-first architecture, we simplify the complexity so your teams can focus on growth. Whether you’re deploying AI in the supply chain, automating stock forecasting, or integrating Microsoft 365 Copilot into daily operations, Techverx brings the technical foundation and business intelligence to make AI work at scale.

Hannah Bryant

Hannah Bryant is the Strategic Partnerships Manager at Techverx, where she leads initiatives that strengthen relationships with global clients and partners. With over a decade of experience in SaaS and B2B marketing, she drives integrated go-to-market strategies that enhance brand visibility, foster collaboration, and accelerate business growth.

Hiring engineers?

Reduce hiring costs by up to 70% and shorten your recruitment cycle from 40–50 days with Techverx’s team augmentation services.

Related blogs